Verfügbare Überwachungsstufen für dieses Produkt

Unsere UV-C-Anlagen bieten verschiedene Überwachungsstufen, die auf jede individuelle Anforderung abgestimmt sind.

Ohne Überwachungsstufe

- Manuelle Inspektion erforderlich

- Unabhängig von Technik nutzbar

ab 612,20€

Zum Produkt

Mit Lebensdauer-überwachung

- Automatische Laufzeitmessung der UV-C-Lampe

- LED-Anzeigen für Status und Voralarme (Grün/Gelb/Rot)

- Einfache Bedienung ohne manuelles Zählen

ab 759,85€

AusgewähltTechnische Daten

Hier findest du alle technischen Spezifikationen.

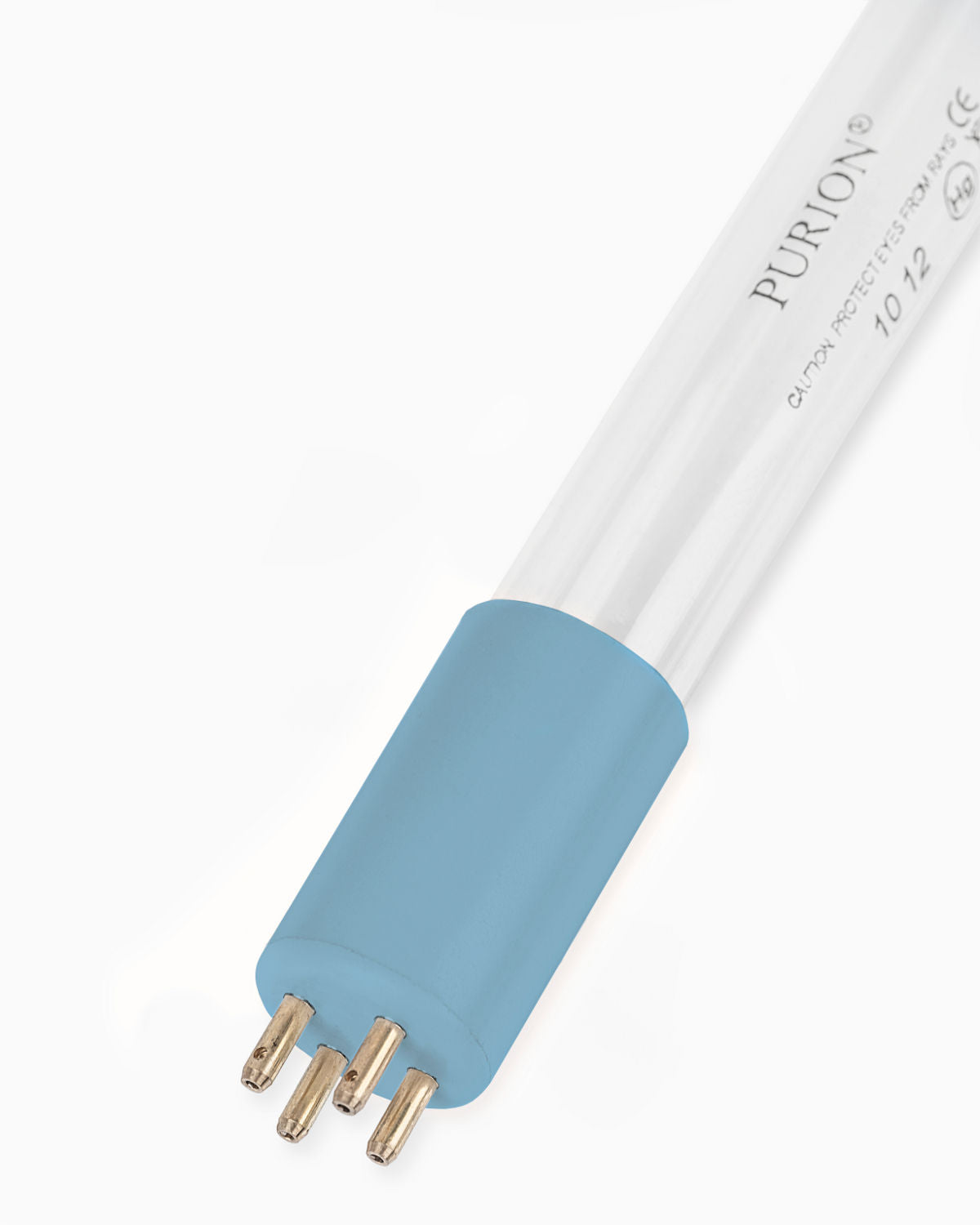

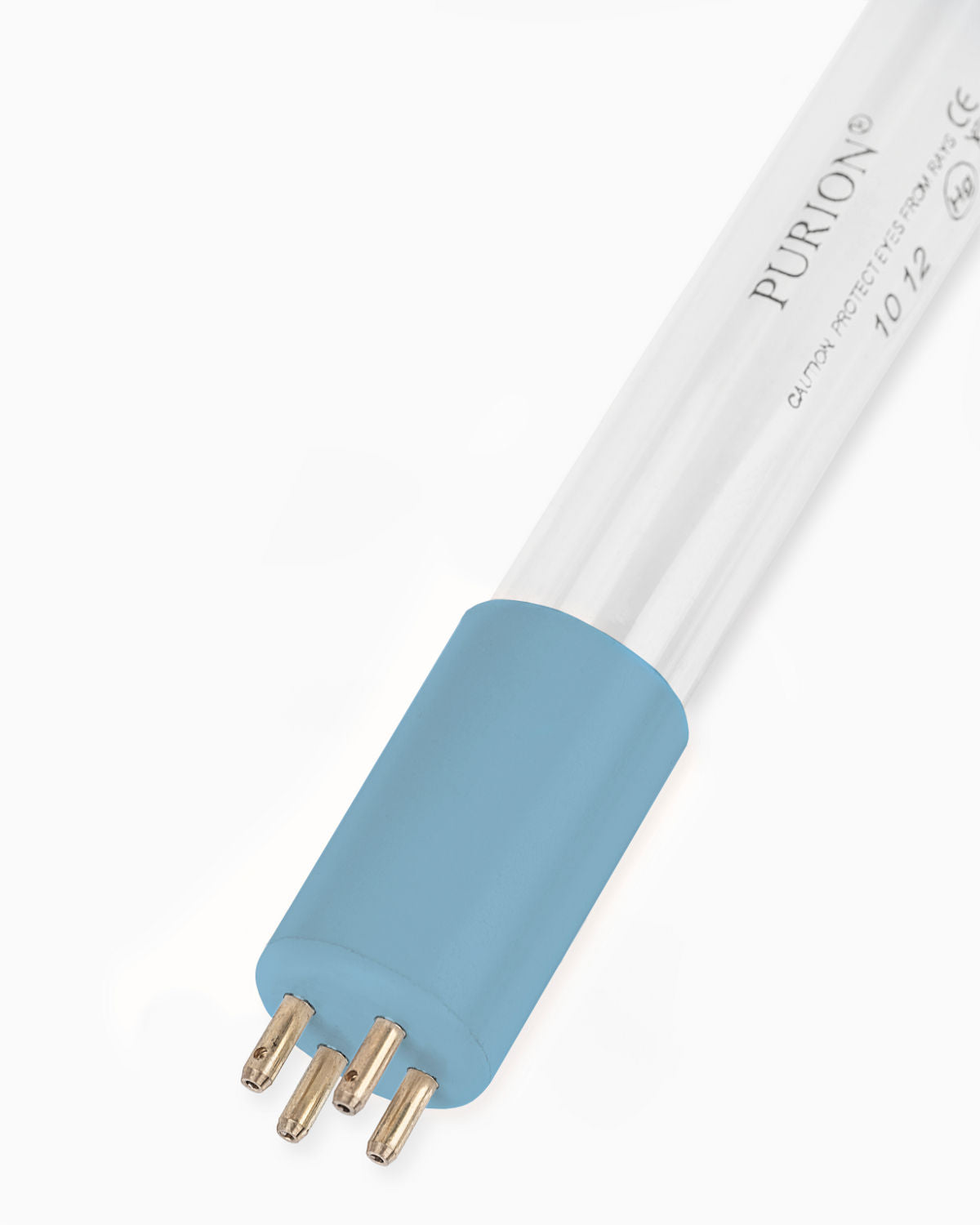

| Hersteller | PURION GmbH |

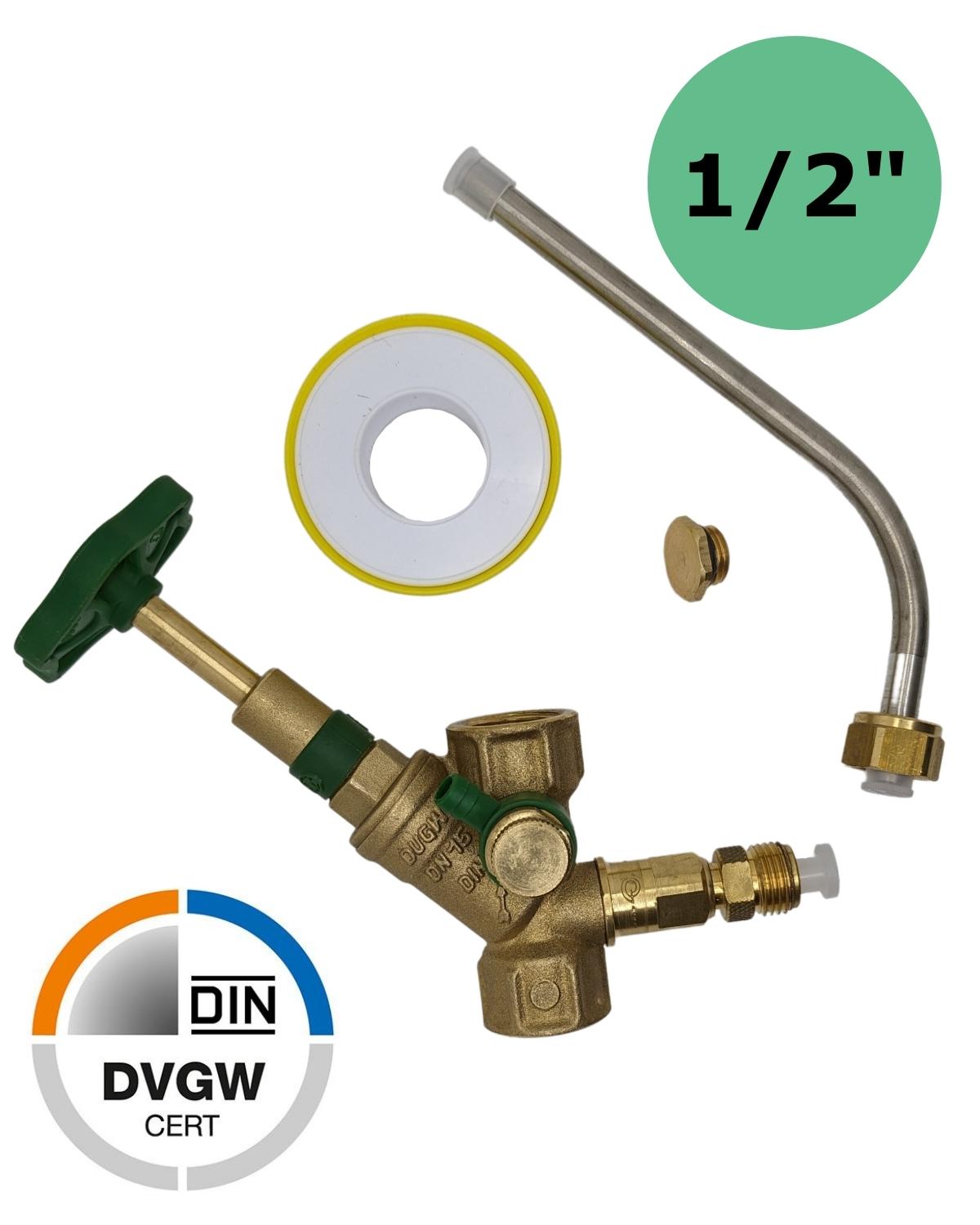

| Anschluss | R 1/2" |

| Reaktor | Stainless steel 1.4571 |

| UVC-Transmission | 20% T1 cm |

| Anlagentyp | PURION 500 Pro |

| Gewicht | 2 kg |

| Dichtung | FPM |

| Wassertemperatur | 2 °C to 40 °C |

| Elektrischer Anschluss | 110 - 240 V / 12 V / 24 V, 50 - 60 Hz |

| Dosis | 400 J/m² |

| Strahlernutzungsdauer | 10,000 h |

| Leistung | 10 W |

| Absicherung | 10 A |

| Durchsatz | 300 l/h domestic water, 200 l/h emulsions |

| Flanschabstand | 255 mm |

| Maximaler Betriebsdruck | 10 bar |

| Anzahl der Strahler | 1 |

| Dimensionen (L x B in mm) | 320 x 42 |

Downloads

Technische Dokumente zum Herunterladen

Lieferumfang

Was im Lieferumfang enthalten ist

Häufig gestellte Fragen

Hier findest du Antworten auf die häufigsten Fragen zu unserem Produkt.

Passendes Zubehör für PURION 500 PRO OTC Plus

Passende Beiträge zum Produkt

Guide to UVC Disinfection: Everything You Need to Know - Drinking Water

Experience the benefits of UVC disinfection: chemical-free, effective, and sustainable – for germ-free and safe drinking water in every household.

Zuletzt angesehen

Alles Wichtige zu Versand & Kauf

Benötigst du Hilfe? Wir sind für dich da!

Telefon: +49 3641 327 9697

Telefon: +49 3641 327 9697

Offizieller Purion Händler

Offizieller Purion Händler

Europaweite Lieferung

Europaweite Lieferung

Datenblatt herunterladen

Datenblatt herunterladen